Guys .... I finished fixing the O2's on Sunday and two days later the light is back on. Thanks to Fred I went to Harbor Freight and picked up the OBDII Trouble Shooter (39.99 with page from their website). Anyway, its reading 174 which according to the manual is a lean condition. What is causing it and how do I fix it????? I am already out about $150.00 and the car is still unsmoggable. Any help would be appreciated.

Announcement

Collapse

No announcement yet.

174 lean condtion now what

Collapse

X

-

clean the mass air flow but be carefull not to break the wires. use some brake or intake cleaner on a end of a q-tip and gently touch the wires.2009 Honda Civic EX- the daily beater

old toys - 1983 trans am, 1988 trans am, 1986 IROC-Z, 2002 Ram Off-Road, 1984 K10, 1988 Mustang GT, 2006 Silverado 2500HD

-

ok but longer term what is a solution ?? Can I keep going with the new MAF or is there some way to resolve it (assuming it is the MAF)?97 TA, M6, JBA ceramic coated headers, Borla Cat-back exhaust, 1.6 RR, 160 Thermo, LT4 knock sensor, CAI, Bils, Hotchkis all around, GT rotors, B&M shifter, Magnecor wires, Granatelli MAF

In the shop LT4 Intake and heads.

Comment

-

Saddly I heard the same thing AFTER I had it but I will hold onto it for when I do the LT4. If nobody else comes up with an alternative I will pull it tomorrow and install the old one.97 TA, M6, JBA ceramic coated headers, Borla Cat-back exhaust, 1.6 RR, 160 Thermo, LT4 knock sensor, CAI, Bils, Hotchkis all around, GT rotors, B&M shifter, Magnecor wires, Granatelli MAF

In the shop LT4 Intake and heads.

Comment

-

P0174 = Bank 2 (passenger side) fuel trim system lean.

The code sets when the average of the long term fuel trims exceeds +21.9%. That means you may only have a "lean" condition on one side. If you had it on both sides, you would also get P0171. Two possibilities - 1) the lean condition is only on the passenger side, and the driver's side is "OK", or 2) the driver's side is also lean, but just hasn't pushed the long term fuel trims far enough to trip P0171.

This is where a scanner that can access the PCM control parameters becomes necessary, since that would allow you to see if you have a lean condition on both sides.

If you only have a condition on one side, you can rule out the MAF, fuel pressure, etc. You would be looking at things like 1) exhaust leaks before the O2 sensor, 2) misfires on that bank, 3) problems with the O2 sensor or sensor harness wires on that side, 4) faulty AIR check valve on that side, 5) low flow in an injector on that side, 6) leaky intake manifold gasket on that side.

If its both sides, 1) low fuel pressure, 2) miscalibrated MAF sensor, 3) MAP sensor indicating high vacuum, 4) fuel contamination.Fred

381ci all-forged stroker - 10.8:1 - CNC LT4 heads/intake - CC solid roller - MoTeC engine management - 8 LS1 coils - 58mm TB - 78# injectors - 300-shot dry nitrous - TH400 - Gear Vendor O/D - Strange 12-bolt - 4.11's - AS&M headers - duals - Corbeau seat - AutoMeter gauges - roll bar - Spohn suspension - QA1 shocks - a few other odds 'n ends. 800HP/800lb-ft at the flywheel, on a 300-shot. 11.5 @ 117MPH straight motor

Comment

-

Fred and all .. thanks for the help. I went ahead and changed out the MAF tonight.

Fred when you say misfire are you referring to the sparkplug on the same side as the O2 that is tripping the code?

Sounds like the things you outlined are over my head in terms of the time, tools and ability to remedy.

The OBDII reader I purchased cleared the code and when I started up the car the light went right out. If the O2 was faulty or the wiring was faulty wouldnt the light be a constant regardless?

Thanks again for any information. I may just have to take the car to the shop when I get back from my honeymoon97 TA, M6, JBA ceramic coated headers, Borla Cat-back exhaust, 1.6 RR, 160 Thermo, LT4 knock sensor, CAI, Bils, Hotchkis all around, GT rotors, B&M shifter, Magnecor wires, Granatelli MAF

In the shop LT4 Intake and heads.

Comment

-

just wondering here since air seems to play a part in this. Would a cracked or broken rubber elbow after the MAF and before the TB cause any of the problems? I noticed it when I changed out the MAF.97 TA, M6, JBA ceramic coated headers, Borla Cat-back exhaust, 1.6 RR, 160 Thermo, LT4 knock sensor, CAI, Bils, Hotchkis all around, GT rotors, B&M shifter, Magnecor wires, Granatelli MAF

In the shop LT4 Intake and heads.

Comment

-

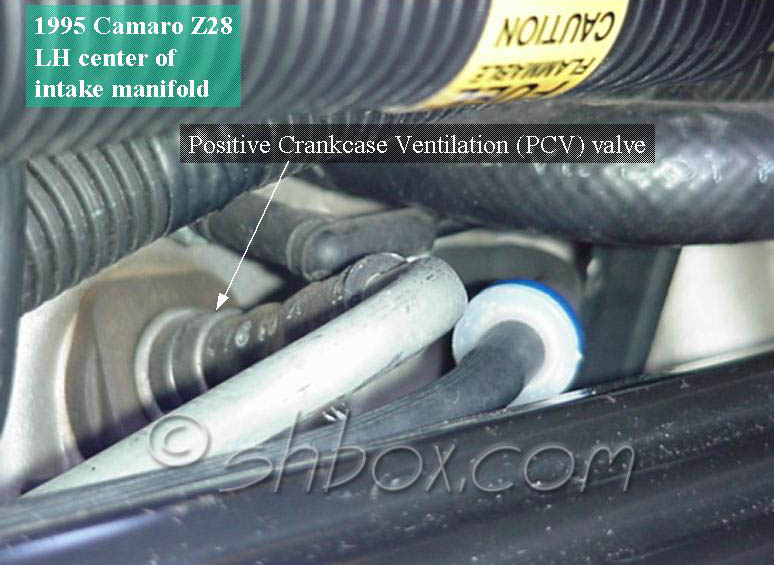

yup. anytime unmetered air enteres after the MAF, you're going to be lean. It could be from several sources.....the elbow, vacuum lines, faulty PCV valve, manifold leak, etc.Originally posted by soCalTAjust wondering here since air seems to play a part in this. Would a cracked or broken rubber elbow after the MAF and before the TB cause any of the problems? I noticed it when I changed out the MAF.

Comment

-

Shoebox has pictures of everything on his website:

Without the clutter, and on a 93/94 (PCV is in same location, vacuum source is different than the 97) it looks like this:

Fred

Fred

381ci all-forged stroker - 10.8:1 - CNC LT4 heads/intake - CC solid roller - MoTeC engine management - 8 LS1 coils - 58mm TB - 78# injectors - 300-shot dry nitrous - TH400 - Gear Vendor O/D - Strange 12-bolt - 4.11's - AS&M headers - duals - Corbeau seat - AutoMeter gauges - roll bar - Spohn suspension - QA1 shocks - a few other odds 'n ends. 800HP/800lb-ft at the flywheel, on a 300-shot. 11.5 @ 117MPH straight motor

Comment

-

OK thanks ...

I will add that to my list of things I can do before I take her in.97 TA, M6, JBA ceramic coated headers, Borla Cat-back exhaust, 1.6 RR, 160 Thermo, LT4 knock sensor, CAI, Bils, Hotchkis all around, GT rotors, B&M shifter, Magnecor wires, Granatelli MAF

In the shop LT4 Intake and heads.

Comment

Comment