I have a 1994 Formula 6-speed. I am on the 4th optispark. Each time I take it apart, the rotor is corroded. I even had a rotor break apart. I am about 90% sure that the water pump is not leaking, and all my vaccum lines are hooked up. I was wondering if you had any other ideas why my optispark keeps getting mostuire in there and getting ruined? Any tests I can do? Thanks alot!!

Announcement

Collapse

No announcement yet.

F-body Experts Only!! Opti-venting problems!?!?!

Collapse

X

-

There is no venting with a 94 opti. A good trick is to run a hose from your weap hole away from your opti just incase. Also check your timing chain cover to make sure its not leaking oil. I'm doing my opti this weekend hopefully and I after looking at it last weekend I'm convinced that its caused by my timing chain leaking oil which I just noticed. The opti is covered in oil. I'll be replacing that while I'm in there.1994 Firebird Formula, M6, Fan switch, 160 thermostat, Pacesetter LT headers, Morosso CAI, TB bypass, True duals.

Comment

-

I have a 1994 with a 96 engine w/ LT4 Hot Cams Package, Ported Heads, and exhaust. I had replaced the enitire distrubtor with AC Delco twice and then they would not replace it any more for free so I got the elcheap discount distrubotor twice and the exact saem thing! No MSD.Originally posted by Joe 1320What mods do you have? Are you replacing the cap and rotor portion with an el-cheapo discount auto parts variety? Are you running an MSD?

Comment

-

Its a 1994 w/ a 96 engine, so it does have venting. Where exactly is the weap hole? I just replaced the front cover gasket and all new seals, so its not leaking for sure....Originally posted by 94 formulaThere is no venting with a 94 opti. A good trick is to run a hose from your weap hole away from your opti just incase. Also check your timing chain cover to make sure its not leaking oil. I'm doing my opti this weekend hopefully and I after looking at it last weekend I'm convinced that its caused by my timing chain leaking oil which I just noticed. The opti is covered in oil. I'll be replacing that while I'm in there.

Comment

-

Are you sure the vent/vacuum hoses for the opti are complete with all the parts and installed correctly?Rob B 95Z A4 Tech Page (Part numbers / locations, how to's, schematics, DTC's...) Home Page - shbox.com

Comment

-

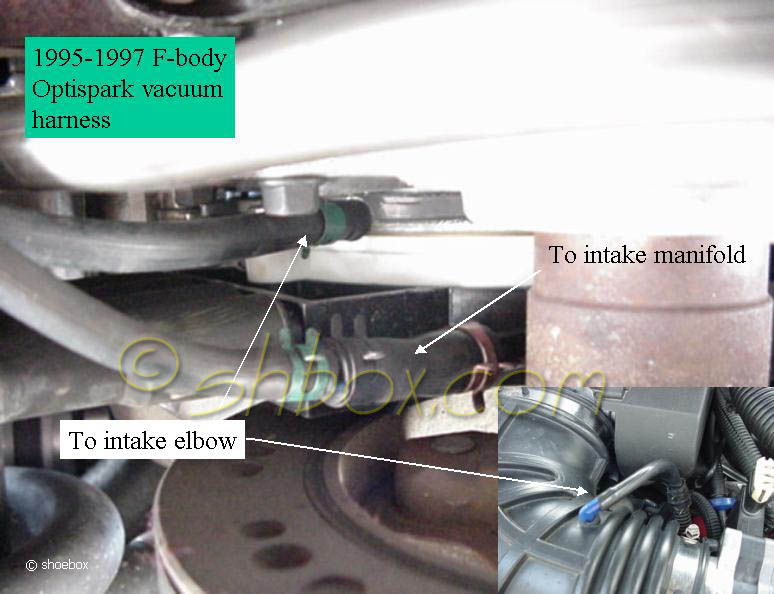

If you have the 95/96 Opti, then you should have 2 vacum hoses that connect to it. One goes from the distributor cap up to the large air elbow in front of the throttle body. The second hose comes off the bottom of the Opti base and goes up to a port on the left side of the intake manifold. These hoses have check valves and filters on them (they may be plugged). The red oxide dust that you find inside the opti is from the bearing dying. The opti can be cleaned.

You can take it apart clean the disk carefully, as well as the other internal parts, grease the bearings and reassemble (mine was good for another 50k). Shoebox has some pictures and directions on his site.

Usually the failure of the opti comes from the failure of the water pump, notice the pumps weep hole right above the opti? while you have it all apart, drill a 3/16" hole in the pumps weep hole, glue in a 3/16" plastic 90 deg. vacum elbow, add about 2' of 3/16" vacum hose and route it over to the steering rack, zip tie the end to the rack. Then when the pump fails, you might notice coolant over by the rack, instead of dripping on the opti.The Old Guy! '94 z-28, m-6, t-tops, go-fast red, 316k. Now with '96 engine w/ Lt-4 hot cam, roller rockers, heavy duty timing chain, and Spec stage 2 clutch.

Comment

-

Frequent failures of the rotor on cars with cam replacements can be related to improper dowel pin length. Have you checked the install to insure that there is not a problem with the dowel pin?

A suggestion... if you are going to ask "tech" questions, include a "signature" with ALL the info required for people to answer the question. By not including the correct info in your initial post, you made it more difficult for people to help you.Fred

381ci all-forged stroker - 10.8:1 - CNC LT4 heads/intake - CC solid roller - MoTeC engine management - 8 LS1 coils - 58mm TB - 78# injectors - 300-shot dry nitrous - TH400 - Gear Vendor O/D - Strange 12-bolt - 4.11's - AS&M headers - duals - Corbeau seat - AutoMeter gauges - roll bar - Spohn suspension - QA1 shocks - a few other odds 'n ends. 800HP/800lb-ft at the flywheel, on a 300-shot. 11.5 @ 117MPH straight motor

Comment

-

z28_xxx

z28_xxx

Pull the vacuum line out of the intake duct.

Stick a vacuum gauge on it with the engine running - you should

be pulling some vacuum (14-15)?

If not - your lines are plugged or they are not hooked up correctly.

You'll probably need to look at another 96 motor and see how that is

routed.

good luck

Originally posted by peteIf you have the 95/96 Opti, then you should have 2 vacum hoses that connect to it. One goes from the distributor cap up to the large air elbow in front of the throttle body. The second hose comes off the bottom of the Opti base and goes up to a port on the left side of the intake manifold. These hoses have check valves and filters on them (they may be plugged). The red oxide dust that you find inside the opti is from the bearing dying. The opti can be cleaned.

You can take it apart clean the disk carefully, as well as the other internal parts, grease the bearings and reassemble (mine was good for another 50k). Shoebox has some pictures and directions on his site.

Usually the failure of the opti comes from the failure of the water pump, notice the pumps weep hole right above the opti? while you have it all apart, drill a 3/16" hole in the pumps weep hole, glue in a 3/16" plastic 90 deg. vacum elbow, add about 2' of 3/16" vacum hose and route it over to the steering rack, zip tie the end to the rack. Then when the pump fails, you might notice coolant over by the rack, instead of dripping on the opti.

Comment

-

Shoebox has photos and vacuum routing diagrams on his "Tech Pages".... 95-97 vacuum line hookups are the same.

Shoebox's Tech Pages

Fred

Fred

381ci all-forged stroker - 10.8:1 - CNC LT4 heads/intake - CC solid roller - MoTeC engine management - 8 LS1 coils - 58mm TB - 78# injectors - 300-shot dry nitrous - TH400 - Gear Vendor O/D - Strange 12-bolt - 4.11's - AS&M headers - duals - Corbeau seat - AutoMeter gauges - roll bar - Spohn suspension - QA1 shocks - a few other odds 'n ends. 800HP/800lb-ft at the flywheel, on a 300-shot. 11.5 @ 117MPH straight motor

Comment

-

There's an online page for swapping in a vented Opti. It includes these part #'s for the vacuum parts:

Opti vacuum harness - 12555323

Opti vacuum fitting - 14082470

http://para.noid.org/~muttvette/opti.html

The blue fitting goes in the rubber inlet bellows. The line from there to the Opti is simply rubber vacuum line. Then from the Opti to the vacuum connection on the drivers side of the intake manifold, they use a slightly larger diameter vacuum hose, and include a small blue/white plastic filter and another blue/white plastic check valve. The dealer harness includes all the parts, but is kind of expensive for what you get. Of course if you use one of the recommend online GM parts dealers (Dal Slabaugh, Jason Cromer) you will pay about 1/2 of what your local dealer would hose you for.Fred

381ci all-forged stroker - 10.8:1 - CNC LT4 heads/intake - CC solid roller - MoTeC engine management - 8 LS1 coils - 58mm TB - 78# injectors - 300-shot dry nitrous - TH400 - Gear Vendor O/D - Strange 12-bolt - 4.11's - AS&M headers - duals - Corbeau seat - AutoMeter gauges - roll bar - Spohn suspension - QA1 shocks - a few other odds 'n ends. 800HP/800lb-ft at the flywheel, on a 300-shot. 11.5 @ 117MPH straight motor

Comment

Can i just buy a kit from somebody somewhere?

Can i just buy a kit from somebody somewhere?

Comment